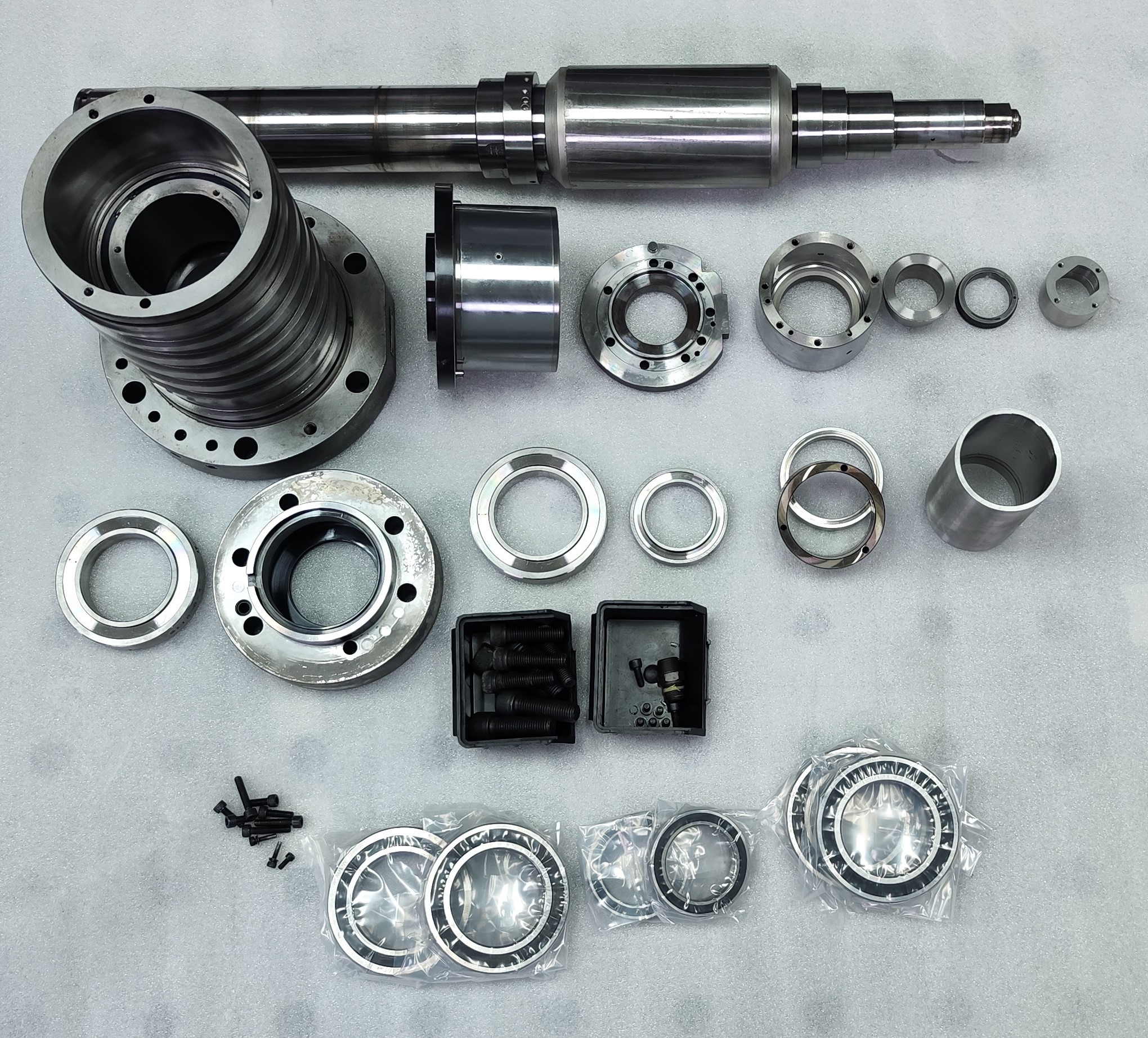

MAZAK 25000 rpm electro-spindle reconditioning

MAZAK electrospindle reconditioning included:

- dismantling the electro-spindle from the MAZAK FJV-250 machine

- transportation to a specialized spindle repair shop

- disassembly of individual components of the electrospindle

- Technical analysis and execution of the time and date offer

- Measurement and adjustment of the service set of hybrid bearings

- Repair and grinding of damaged components

- cone grinding

- tool gripping test

- cleaning and preparing components for assembly

- replacement of tool clamp springs

- Bearing selection and size matching

- installation of a headstock and a new set of bearings

- installation of individual components

- measurements after assembly

- start of rotation

- short start-up

- installation on the balancing machine and setting of balancing parameters

- 0.4G class balance

- printout of the balancing protocol

- start of rotation

- gradual lapping

- measurements of electrical parameters of windings

- protocol of electrical parameters

- two-day lapping

- checking the operation of the tool's engagement mechanism

- tool gripping test

- RPM converter test

- proximity sensor test

- execution of the repair protocol

Electrospindle (or spindle) reconditioning is the process of restoring the efficiency and performance of worn or damaged electrospindles. It involves repairing, replacing worn parts such as bearings and other components, and restoring the original parameters. Our company always performs comprehensive remanufacturing services so as to restore full efficiency to service.

The purpose of the remanufacturing was: to restore full functionality of the spindle, thus avoiding costly replacement with a new one. The customer can continue to fully operate his machine tool.

Comment on SpinX Group Cancel writing reply